Cold Chain Monitoring Case Study: IceConnect Plug & Play sensor

A third of the food produced globally is wasted, with much of that loss occurring along the global cold chain. Overall, that translates to 1.6 billion tons of food, worth about $1.2 trillion, down the chute. While low prices and frequent promotions drive consumers to the store, food quality and freshness is often their biggest concern, making temperature monitoring a critical operation for retailers.

Challenges

Manage remotely, a large number of refrigerated furnitures throughout the country. Monitor the energy consumption of refrigerators and receive alerts in case of malfunction to ensure compliance with temperature requirements from regulatories.

Solution

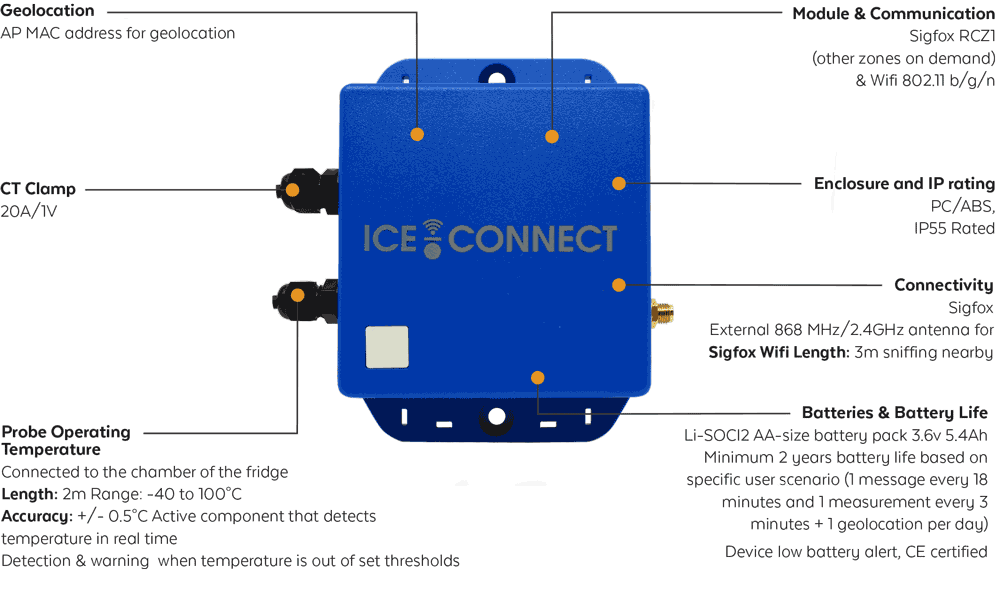

A cost-efficient, low-power industrial-grade tracker with a temperature sensor that lasts for at least 2 years.

Results

• 15% reduction in food waste.

• New revenue from value-added services.

• High-quality temperature control and reporting that meets regulatory guidelines.

Loca Service is a leading refrigerated furniture rental company headquartered in France that has been providing tailor-made rental service for large and medium-sized retail stores (supermarket and hypermarkets), and food manufacturers in Europe for the last 40 years.

With a network of 12 agencies throughout Europe, Loca Service has a catalogue of over 300 products and over 38,000 refrigeration displays in circulation, including the stores of Auchan, Carrefour, Monoprix, Starbucks, Pepsico and Danone.

As an expert in refrigeration, Loca Service wants to design a cost-effective and reliable reporting solution for clients to maintain proper control of their refrigerators without the need for time-consuming and costly manual data collection.

Automated readings guarantee specific cooling conditions, better food preservation and significant savings while complying with strict regulations.

A CHILLING PROBLEM

Refrigeration monitoring is not only a regulatory requirement but a crucial part of F&B operations with real consequences.

Those who have experienced a loss of inventory due to a broken refrigerator, or worse, sold food that was compromised unknowingly, causing food poisoning, can attest to how painful such an experience can be. While the loss of inventory and time (to repair the refrigerators) is temporary, negative publicity and the permanent loss of customers can affect businesses in the long run or even cause them to shut down.

Traditionally, retail stores have refrigerated display cases to keep food such as dairy products, fish, meat or drinks at specific cooling temperatures. The use of these display cases requires multiple daily visits to the fridges (minimum twice a day) to guarantee that the temperature conditions are well maintained. Temperature data are collected and reported manually in Excel sheets, and these data logs are kept in store for at least 12 months in accordance with HACCP standards.

This labour-intensive procedure is not only cumbersome and inefficient but also subjected to human errors. On top of that, they are not performed or accessible during store closing hours.

For retailers, food must be carefully monitored to ensure shelf life and food safety. However, the quality control of an ever-expanding range of produce and products are laborious and costly due to different temperature and handling requirement.

WHAT IS HAZARD ANALYSIS CRITICAL CONTROL POINT (HACCP)?

Hazard Analysis and Critical Control Point (HACCP) is used in the food industry to identify potential food safety hazards, so that key actions, known as Critical Control Points (CCPs) can be created to reduce or eliminate the risks.

HACCP helps F&B industry to put in place an effective integrated food safety management to ensure safety and traceability. The implementation of a Food Safety Management System based on HACCP principles is a legal requirement.

KEEPING YOUR COOL

The solution is designed to send location and temperature change data to Loca Services so that their customers can take swift measures to change fridges or move products if necessary.

In the event, when the power of the fridge goes below the minimum threshold, a warning will be sent to the customers by email and in push notification via mobile phone apps to inform their customers of a possible breakdown. However, should the temperature returns to normal, a second alert will be sent.

NEVER LOSE INVENTORY AGAIN WITH REFRIGERATION MONITORING

Since the implementation of the IoT solution, Loca’s customers receive regular update on their refrigeration assets helping them to:

Reduce loss of perishables by 15%

Monitor energy consumption of equipment

Be alerted when temperature have veered out of their normal ebb and flow via the mobile application, email, or text messages

Improve the management of every rented fridge. e.g. to send malfunctioning refrigerators for repair or replacement

Simple & Fuss Free Installation

No Cabling

No Additional Infrastructure

No More Manual Readings

• Cloud based software

• Personalised & Secure Access 24/7

• Display Temperature Data Remotely, in Real-Time

• Exportable in PDF, Excel or CSV format

• Easy Integration to customers’ IT systems

• Daily reports of temperature in graphs, and locations

indoor or outdoor, including location history

The idea of Ice-Connect came to fruition when we met UnaBiz and IoThink. In order to develop a high-quality product, we need very high precision components such as the external antenna and temperature probe. UnaBiz’s R&D team’s expertise in product design and manufacturing allowed us to achieve a highly customised product within a short time span.

Sylvain LEHUT – IT Manager of Loca Service

Loca Service’s team is made up of dedicated professionals who share a passion for refrigeration and their solutions can be adapted to many businesses and different uses. As the cooling industry expert, they want to provide integrated management of the refrigerated displays for their clients to help them build strategic decision-making tools within a reasonable budget. UnaBiz comes in as an expert in Sigfox 0G Network to help Loca Service optimise Ice-Connect’s hardware with the latest technological innovations. We also work closely with IoThink, the technical partner of Ice-Connect for integration data processing and local support as well.

Nicolas BAELE – Global Solution Specialist of UnaBiz